|

Tool data can reach the machine control system in a variety of ways. To ensure that the data

|

|

|

|

Dear [FIRSTNAME],

Tool data can reach the machine control system in a variety of ways. To ensure that the data can be clearly assigned to the corresponding tool, unique identification is an absolute must. One possibility is to identify each tool assembly uniquely with a data matrix code – an inexpensive and simple technology.

|

|

TOP STORY |

|

|

|

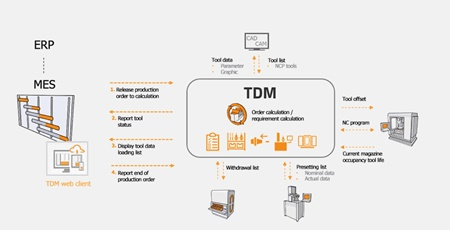

Digitalization shift on the shopfloor

Strong on-time performance and productivity with falling costs – the goals of many companies are ambitious. Without intensified digitalization and automated processes, these are impossible to achieve. Current trend: Connecting production machines to the TDM tool management solution. Major benefit: automated data exchange eliminates error-prone data input at the machine completely and shortens setup times drastically. More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

Asia-Pacific most receptive to smart manufacturing usage globally

More than ever, manufacturers are turning to smart technology to overcome challenges while making processes faster and more effective. The State of Smart Manufacturing Report reveals that Asia-pacific organizations are most receptive to smart manufacturing usage globally. The research says that smart manufacturing adoption accelerated by 50% globally in 2021, and these new technologies are now solving the industry’s critical challenges.

More...

|

|

|

SMART research reveals uses of non-destructive sensors to aid food security

A published a review that discusses the recent advances in non-destructive plant health monitoring, ranging from electrochemical-based arrays to nanosensors and electronic noses, and why tracking plant health is an attractive and sustainable strategy that can be used to optimise crop growth practices. The review aims to inspire future developments of non-destructive technologies for plant health diagnosis. More...

|

|

|

Using automation to leverage the full potential of machine tools

Automation is one of the most important ways in which manufacturing companies can raise their productivity levels and thus remain competitive. And many solutions are now easier to implement today than they were just a few years ago. Furthermore, investments in this segment are now paying for themselves ever faster. This, in turn, is making the systems increasingly attractive for small and medium-sized enterprises. More...

|

|

|

Perspectives on the adoption of smart solutions: A panel discussion

An online panel discussion during the recent ASEAN Electronics and Semiconductor Manufacturing Summit 2022, titled: Digital Transformation, Smart Manufacturing, wherein Dr. Danilo C. Lachica, President of SEIPI, Mr. Rhett Ramos, Director of Asia IT and Smart Manufacturing Director, Allegro MicroSystems, and Mr. Sherwin C. Nones, Head of Strategic Planning and Marketing from IMI, answered two of the most sought after questions from the attendees. More...

|

|

|

Hexagon, ESAB to help manufacturers optimise robotic welding processes

Producing successful welds can be challenging without the benefit of many years’ shop-floor experience and, even with an extensive welding experience, can incur high costs from waste and time. Hexagon’s simulation intelligence, embedded within ESAB’s software and automation portfolio, will ensure that users have the tools required to consistently manufacture high-quality products without costly trial and error. More...

|

|

|

FruitSmart receives certification from Upcycled Food Association

FruitSmartTM fiber ingredients have been awarded the Upcycled Food Association’s (UFA) new certification mark. FruitSmart specializes in premium fruit-based ingredients. Well regarded for its not-from-concentrate apple juice, its range also includes fiber products from apple and blueberries. They can enhance consumer appeal, for example by enabling health claims, as well as providing manufacturing functionality such as moisture retention. More...

|

|

|

|

|

|

|

|

|

|